Products

- Cutting Sonotrodes made of Titan

- desigend with FEA analyzis

- manufactured on CAD/CAM 5axis CNC machines

- tested for food us

- Documentation by Lasermarking

- Continuous and intermitted cutting process

- Compact design

- desigend with FEA analyzis

- Ultrsonic Cutting Disc

- diameter 100 and 150mm

- special size upon request

- rotating and non-rotating cutting process

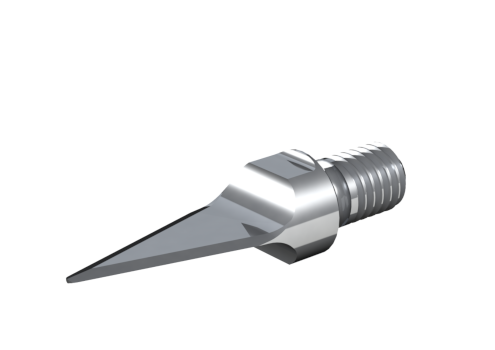

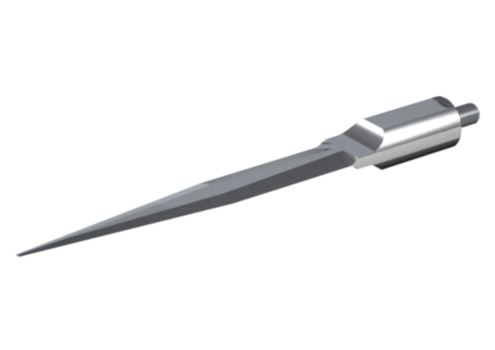

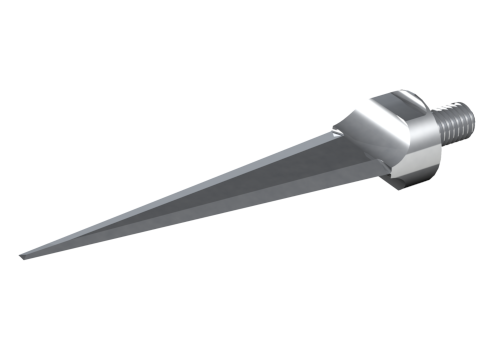

- Monoblock blades

- Designed and developped based on FEA analyzis

- Several times regrindeable

- Made of a monoblock HARTMETALL

- Monoblock Klingen aus Hartmetall

- NO material mixes

- NO damping and losses thru material mixes

- Design of the blades upon application request

- High amplitude up to 40µm

- => provide best cutting performance

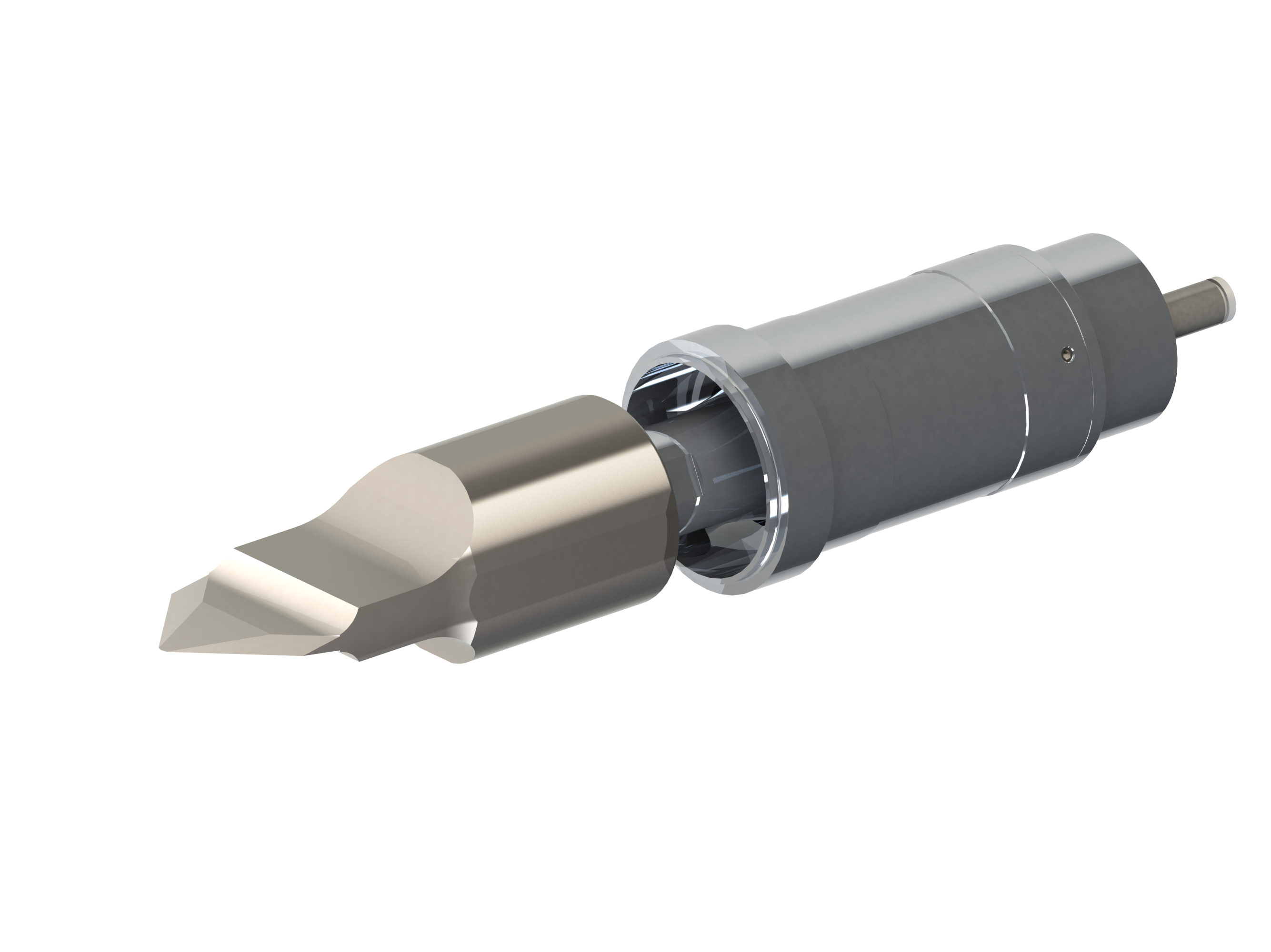

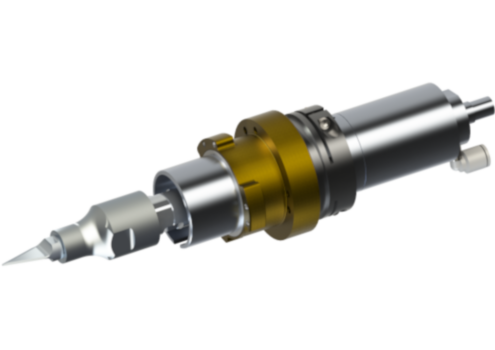

- Ultrasonic converter

- Standard frequencies 20,30, 35 and 40kHz

- IP protection 50; 65 and 68

- Rigid mouting solutions

- Aluminium und Stainless steel housings

- Internal mounted rotating coupler

- Cutting Systems for Integration

- Tooling interface HSK 63 A

- Tooling interface HSK 63 f

- Quick Change tooling systems for Robot and Portal Systems

- Automatic tool change systems for Robot solutions

- Automatic tool change systems for CNC machines

- Customized solutions for x/y Cutter (2D-Plotter)

- Tooling interface HSK 63 A

- Ultraschallgenerator NuSonic

- Analysation

- All generators are standardly equipped with an analysis network port. Therewith all data can be evaluated simultaneously with the bus operation. Local or via remote-maintenance - on any Laptop!

- Connectivity

- Various analogue and digital IO-ports are standard equipment. They assure an easy and permanent comparison between target values and actual values

- Everything under control

- All generators are equipped with a full-colour OLED screen displaying all important information clearly at one glance. 4 individual buttoms allow a test- and emergency run.

- Modern interfaces – Industrie 4.0

- All generators are optionally available with PROFINET, Ethernet TCP/DUP, EtherCAT, EtherNet/IP, Modbus TCP and Modbus UDP interfaces. The preferred bus interface can be activated via SoftwareTool conveniently, without requiring any additional modules.

- Legacy-Connections

- Additional to the modern ethernet-based interfaces, our Generators can be connected via classic interfaces with optional modules.

- This includes:

- RS232

- RS485

- Profibus/ProfiNet

- CAN-Bus (CanOpen)

- Full quality control at all times, on any place – worldwide!

- For our generator to meet the standards of the Industrie 4.0 has been the core demand during its development. The extremely facilitated reaction time of its the troubleshooting surpasses modern requests of quality and reliability. With an optional 64 gigabyte memory all measurements as well as error values are recorded. Therefore the acquisition of data and the transparent display with the GenConfig-Tool is easy and leads to fast results. This guarantees an optimised process flow and consistent quality control at all times.

- 17 - 70 kHz One4All

- The new One4All concept opens the door to an entirely new application spectrum and allows to run any cutting device at any frequency. One Generator for all frequencies. Furthermore, it is suited for any power supply system (90V-280V – 50/60 Hz) due to its far range power supply.